Just over 6 months ago, I purchased a 3D printer. This

acquisition has made my prototyping efforts incredibly easy, since my ideas and

designs can quickly become a reality, with minimal space and production cost.

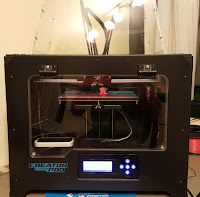

The printer I have is a Flashforge Creator Pro, which has dual extruders, heated print bed, and is able to be completely enclosed to keep in heat. So far I have only used ABS and PLA filaments, but the machine can easily accept most types of filament including nylon, ninjaflex, HIPS, etc.

Prior to having a 3D printer of my own, I made use of the 3D printer and 2D CNC router for the company I was working with at the time.

As a prototype device, 3D printers are excellent - the allow for small prices to be rapidly created with minimal machinery and expense. Unfortunately, 3D prints are only prototypes - they do not have the strength of a properly finished part, because they are created in layers, and are hollow with infill (usually). Additionally, 3D printers take time - and plenty of it! My current prototypes take up to 3 hours to print, though they are fairly small.

For a finished product, I will be endeavoring to use a CNC router.

This allows for a much faster production run (~30s per part), a much stronger part (solid plastic), and an overall cheaper part (after the initial setup costs).

No comments:

Write comments